The company Pontenossa S.p.A. uses the Waelz process to extract non-ferrous metals from electric arc furnace dust (EAFD).

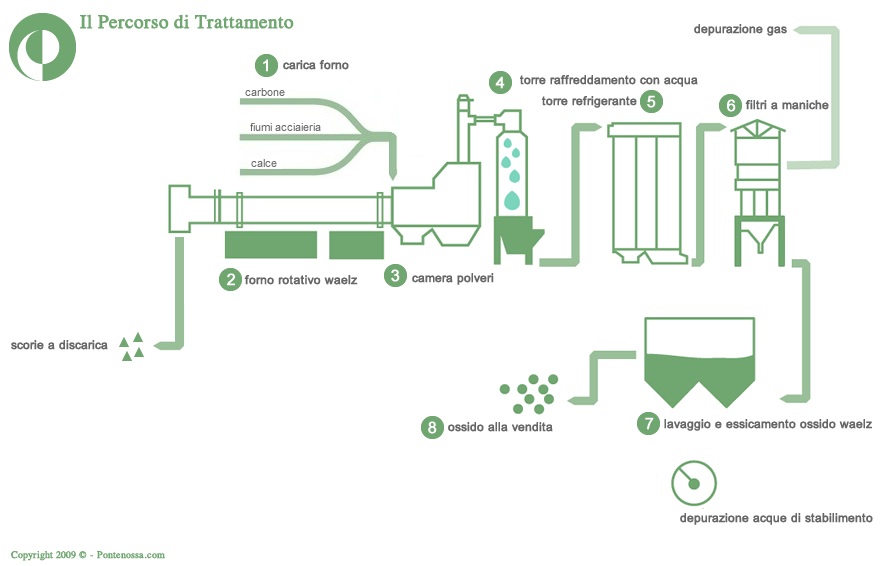

The Waelz technology is in use since many years, originally introduced for the enrichment of low grade zinc ores, in seventies was successfully applied on the treatment of EAF dust, first in Germany, then in Italy and finally in other European and non-European (Japan and USA) countries. The Waelz process uses a rotary kiln as key equipment. The EAF dust is mixed with coal and lime and fed into the kiln. Zinc and lead are reduced from the coal and volatilized thanks to the high temperature. The oxidizing flue gas that flows in counterflow to the charge re-oxides the metals. Zinc and lead oxides are recovered from the gas flow through filtration systems. The product obtained is named “Waelz oxide”.

The production of the Waelz oxide is a key point in the closure of the material loop between the steel and the zinc industry. It finds varied applications in different industrial sectors and enables the steel industry to limit its environmental impact.

Even though pilot plants for other processes have been developed and tested, the Waelz process is the most diffused in the world and is notified in the BREF notes of the European community as the Best Available Technology for EAF dust treatment. The alternative to the Waelz process is the disposal of the dust in a special landfill after concrete addiction to avoid the possible release of heavy metals in the leachate.

Il percorso di trattamento